FLAT BED PAPER BELT FILTER

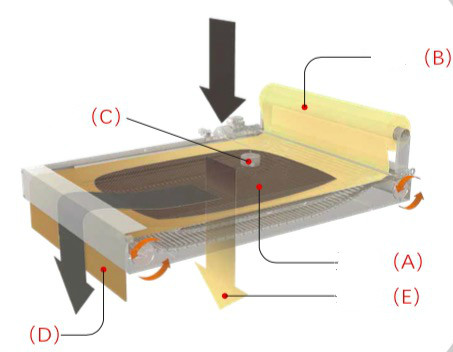

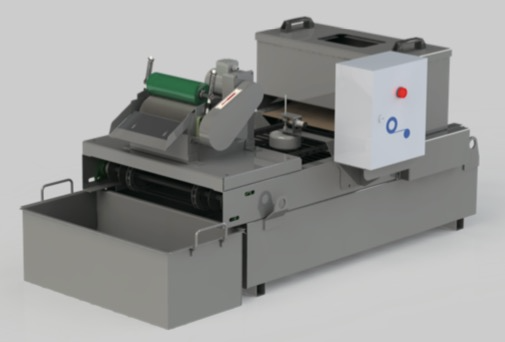

The flat bed paper belt filter mainly includes liquid tank, waste slag tank, filter cloth, transmission mechanism, signaling mechanism, reduction motor and liquid pumping pump, etc. The machine can automatically replace the press cloth. After the press cloth is updated, the machine stops rotating and enters the next working cycle. The clean filtrate entering the tank is transferred to the main engine by the pumping pump.

The filter can remove all kinds of gold, nonmetal and other fine impurities in the coolant (oil). The paint is suitable for all kinds of grinding machines and honing machines. When there are more paramagnetic substances in the filtrate, a two-stage filtration can be carried out by adding a magnetic separator, which can effectively reduce the consumption of the press cloth and improve the filtration effect.

The working principle:

1. The condensed liquid contaminated with impurities is collected in the trough and distributed on the filter cloth, leaving contaminated particles and allowing the clean liquid to flow out.

2. The mesh gradually accumulates contaminated particles until it is blocked, at which point the liquid can no longer pass through the mesh. The liquid level rises and the buoy is lifted, allowing a microswitch (or a probe system) to move the belt forward, so replace the used mesh with a new one.

3. The used cloth is collected into a special small cylinder located at the foot of the purifier, and the filtered liquid flows to the collecting cylinder below, and then is re-sent to the machine tool by a special electric pump.

MODEL | MAX CAPACITY (Emulsion) | MAX CAPACITY (Pure oil) | Pump head | POWER. W | CURRENT DRAIN. A | WEIGHT | ||

| L/MINUTES | L/MINUTES | M | 50HZ | 60HZ | 380V-50HZ | 380V-60HZ | KGS |

JX-BPF-25 | 25 | 13 | 4 | 155 | 155 | 0.42 | 0.42 | 98 |

JX-BPF-50 | 50 | 25 | 4 | 165 | 165 | 0.49 | 0.49 | 121 |

JX-BPF-75 | 75 | 38 | 4 | 350 | 350 | 0.95 | 0.95 | 137 |

JX-BPF-100 | 100 | 50 | 4 | 385 | 385 | 1.13 | 1.13 | 181 |

JX-BPF-150 | 150 | 75 | 4 | 455 | 455 | 1.27 | 1.27 | 225 |

JX-BPF-200 | 200 | 100 | 4 | 470 | 470 | 1.33 | 1.33 | 346 |

JX-BPF-300 | 300 | 150 | - | - | - | - | - | - |

JX-BPF-400 | 400 | 200 | - | - | - | - | - | - |

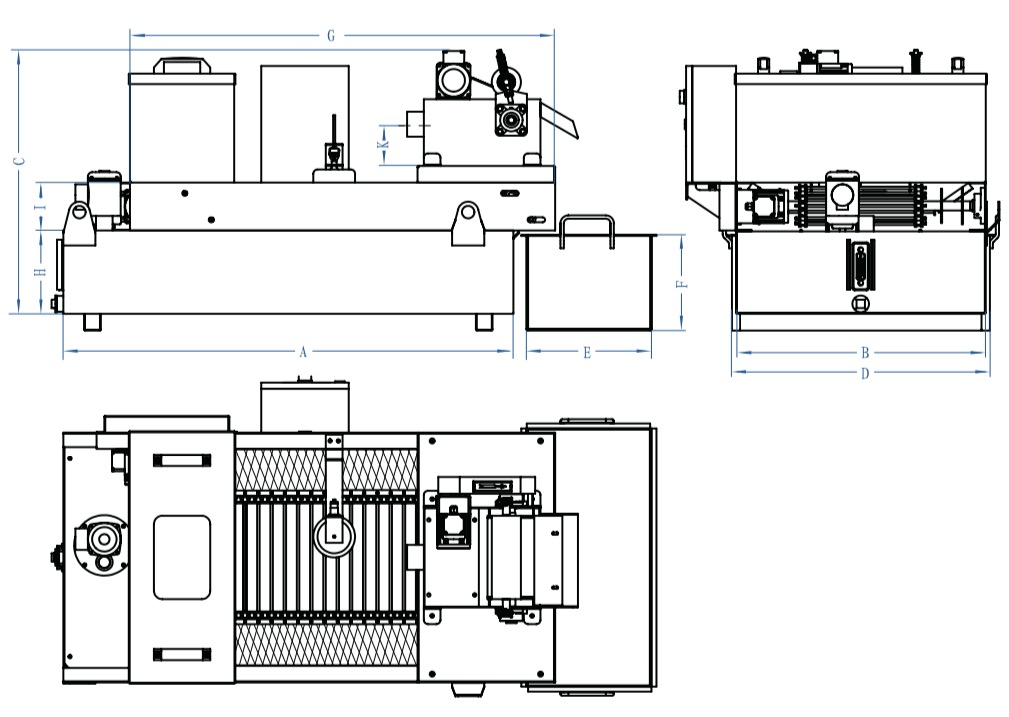

MODEL | SIZE | |||||||||

| A | B | C | D | E | F | G | H | I | K |

JX-CMS-25 | 930 | 480 | 665 | 500 | 250 | 180 | 865 | 200 | 115 | 100 |

JX-CMS-50 | 1080 | 600 | 665 | 620 | 300 | 230 | 1020 | 200 | 115 | 100 |

JX-CMS-75 | 1150 | 600 | 735 | 620 | 300 | 230 | 1100 | 255 | 115 | 100 |

JX-CMS-100 | 1350 | 800 | 745 | 820 | 300 | 250 | 1195 | 255 | 115 | 110 |

JX-CMS-150 | 1500 | 800 | 755 | 820 | 300 | 250 | 1300 | 255 | 115 | 120 |

JX-CMS-200 | 1650 | 1100 | 775 | 1120 | 350 | 250 | 1450 | 255 | 145 | 140 |

JX-CMS-300 | - | 1100 | - | 1120 | 350 | - | 2000 | - | 145 | 300 |

JX-CMS-400 | - | 1300 | - | 1320 | 400 | - | 2500 | - | 145 | 350 |