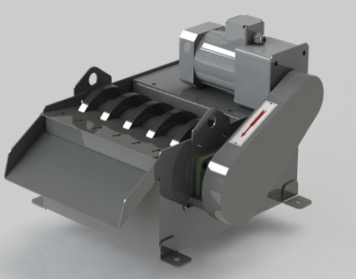

Comb Magnetic Separator

The comb magnetic separator is composed of reducer motor, body, comb tooth magnetic roller and scraper. The deceleration motor drives the magnetic roller to rotate and operate. After the coolant containing the powder paramagnetic substance enters the box, the impurities are adsorbed on the surface of the magnetic roller. Finally, the impurities are separated from the magnetic roller by the scraper.

As an improved product, the comb type magnetic separator is made into comb tooth shape with the same length of magnetic roller, which greatly increases the adsorption surface area. The outer leakage ring ensures the maximum magnetic force, the separation efficiency is significantly improved, especially suitable for the centralized treatment of large flow coolant, can separate granular chip.

Application: all kinds of grinding machines, powder coating lines, rolling Steel waste water purification, bearing processing waste liquid and other coolant containing granular impurities the occasion.

The working principle :

•1 The contaminated liquid is rotated through the disk so that the contaminated magnetic particles are captured.

•2 Waste slag is discharged into the collection box.

•3 The purified liquid is collected into the collection cylinder below and re-pumped into the machine by a special electric pump, or collected by a second purifier for more detailed filtration.

•4 comb toothed magnetic separator is often used together with flat bed paper belt filter and drum paper belt filter.

MODEL | MAX CAPACITY(Emulsion) | MAX CAPACITY(Pure oil) | POWER. W | CURRENT DRAIN. A | WEIGHT | ||

| L/MINUTES | L/MINUTES | 50HZ | 60HZ | 380V-50HZ | 380V-60HZ | KGS |

JX-CMS-25 | 25 | 13 | 25 | 25 | 0.07 | 0.07 | 16.9 |

JX-CMS-50 | 50 | 25 | 25 | 25 | 0.09 | 0.09 | 18.7 |

JX-CMS-75 | 75 | 38 | 60 | 60 | 0.17 | 0.17 | 26.4 |

JX-CMS-100 | 100 | 50 | 60 | 60 | 0.19 | 0.19 | 33.5 |

JX-CMS-150 | 150 | 75 | 60 | 60 | 0.2 | 0.2 | 42.6 |

JX-CMS-200 | 200 | 100 | 120 | 120 | 0.37 | 0.37 | 48.5 |

JX-CMS-300 | 300 | 150 | 120 | 120 | 0.37 | 0.37 | 105 |

JX-CMS-400 | 400 | 200 | 150 | 150 | 0.44 | 0.44 | 128 |

* Rated flow data for the maximum concentration of 5% oil or pure oil, the maximum viscosity in 40 degrees for 20CST emulsion, and the weight of the filter cloth does not exceed 35 grams per square meter. Different properties of the liquid to be treated, the type of pollutant and the corresponding concentration will significantly affect the efficiency of the purifier.

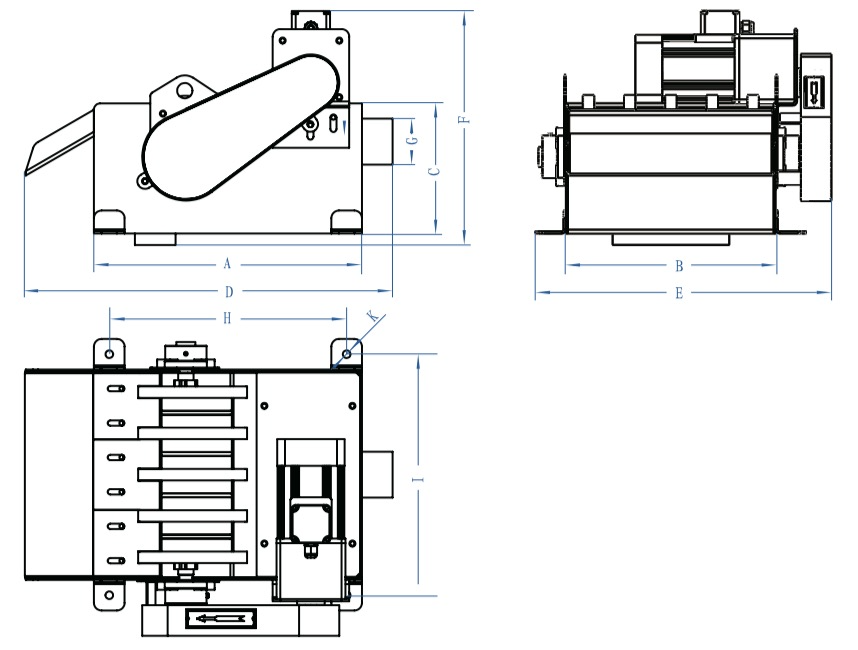

MODEL | SIZE | |||||||||

| A | B | C | D | E | F | G | H | I | K |

JX-CMS-25 | 350 | 235 | 160 | 480 | 315 | 290 | 2" | 310 | 275 | Φ10 |

JX-CMS-50 | 350 | 275 | 170 | 480 | 355 | 305 | 2" | 310 | 315 | Φ10 |

JX-CMS-75 | 390 | 375 | 180 | 520 | 520 | 320 | 2" | 350 | 415 | Φ10 |

JX-CMS-100 | 400 | 485 | 180 | 530 | 535 | 320 | 2" | 360 | 525 | Φ10 |

JX-CMS-150 | 410 | 565 | 190 | 540 | 615 | 330 | 2" | 370 | 505 | Φ10 |

JX-CMS-200 | 460 | 595 | 200 | 590 | 715 | 335 | 2" | 420 | 635 | Φ10 |

JX-CMS-300 | 870 | 635 | 220 | 1115 | 495 | 250 | 3" | 810 | 675 | Φ10 |

JX-CMS-400 | 970 | 705 | 260 | 1215 | 565 | 290 | 3" | 910 | 745 | Φ10 |